Table of Contents

- What is a regulator?

- Types of regulators

- Using a regulator

- Common mistakes

- Maintenance and care

- Price range

If you're interested in learning more about the equipment scuba divers use, check out this article, which talks about all the equipment pieces.

What is a regulator?

When diving, we store all the air we breathe and use in our scuba tank. Because there is a lot of air, it has to be compressed (usually to about 200 bars, or 2900 PSI)! We can not breathe straight from the tank as it would quickly transform us into an overinflated balloon! It is important to make sure that the air we breathe is at the same pressure as the surrounding environment; i.e. if we breathe on the surface, we need to breathe air at a normal pressure of 1 atmosphere (or about 14.5 PSI), but if we breathe at a depth of 10m, and are subjected to a total pressure of 2 atmospheres, we need to breathe air that is also at 2 atmospheres of pressure. This is the regulator's job: to regulate the pressure of the gas it delivers to be equal to the outer environment's pressure.

This reduction in pressure happens in two steps:

- Firstly, the high-pressure gas from the tank has to be reduced to an "intermediate pressure" that can flow through the low-pressure hoses. This high-to-intermediate transition happens in the first stage of the regulator: the first stage is the part that connects directly to the tank. It gets reduced to a pressure that is about 8-11 bars above the ambient pressure at all times. (The SPG, or Submersible Pressure Gauge, is connected to a high-pressure port on the first stage, before the pressure reduction takes place, as it is necessary to see how much gas is left in the tank!).

- This intermediate pressure, although reduced, is still too high to breathe directly and therefore requires a second phase, where it will be further reduced to a breathable pressure. This happens in the second stage: it is the part where the diver directly breathes from. On second stages, there is an air entry from the hose; an exit (through the mouthpiece and the exhaust); a purge button in the back of the second stage used to clear the second stage of any liquid, such as water or spit; and an adjustment knob, used to increase/decrease the required breathing effort.

Regulators do more than just allow the diver to breathe: There is usually a low-pressure hose attached to the first stage used to inflate the BCD/Wing, and there can also be additional ports for a drysuit hose. As mentioned before, there is also a high-pressure port, where the pressure gauge (or Submersible Pressure Gauge, or SPG for short) is connected, and allows the diver to monitor how much pressure is left in the tank. Some computers have transmitters that connect to those ports, allowing the pressure of the tank to be monitored directly from the dive computer!

Types of Regulators

Although regulators have a single purpose, the way some operate or connect to the tank differs. Let's have a look at what exists and what your options are.

Yoke

Yoke connectors, also known as CGA 850 Yoke connectors, or A-clamps, are a clamp-style connection between the tank valve and the first stage. Yoke regulators are the most widespread type of regulators on the market, and are the most common type in North America. The connection screws on either side of the tank valve and "clamps down" on it. The O-ring sits in the opening of the valve and seals the opening when the valve is turned on. Yoke regulators should not be screwed-on too tightly, as they incur the risk of not being able to be opened again by hand. Contrarily, if they are not screwed in enough, there might be a failure with the O-ring seal, and it might create a leak.

Advantages of Yoke regulators: As they are very widespread, there is a greater chance for compatibility with tanks if you travel, although we always recommend bringing a DIN-to-Yoke insert with you to be sure you can use your regulator in a DIN-only dive center!

Disadvantages of Yoke regulators: Yoke connectors are sensitive to impacts and aren't as sturdy as their DIN counterparts.

DIN

DIN (which stands for Deutsche Industrie Norm), although less common worldwide, is the prevalent type in Europe and in technical diving circles. It is a screw-in connection type that screws-in directly into the tank valve. For DIN regulators, the O-ring sits on the regulator, and not in the tank (contrary to yoke regulators, where the O-ring is found on the tank valve). Two main types of DIN regulators can be found on the market:

- the 5-thread (G5/8) screw, which is rated to a working pressure of 232 bars

- the 7-thread (G5/8) screw, which is rated to a working pressure of 300 bars

Advantages of DIN regulators: DIN regulators are considered safer, sturdier, and more resistant to impacts, and are therefore used by technical divers. As can be seen above, they also have the potential of being used with higher pressure.

Disadvantages of DIN regulators: As DIN regulators are less prevalent, if you have one, you might have to travel with a yoke-to-DIN adapter to make sure you can use it with every tank!

Piston or Diaphragm first stage

A first-stage regulator can either be a piston-type or a diaphragm-type.

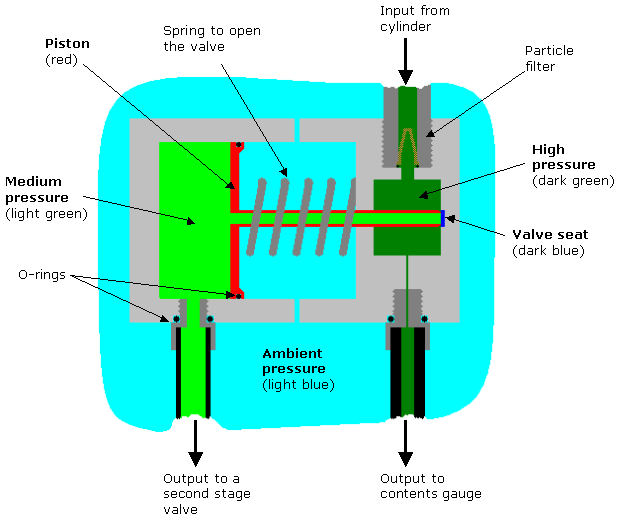

In a piston-type first stage (as shown below), the piston acts as a seal sitting on the valve seat. When the diver inhales, the pressure in the intermediate pressure chamber (shown in light green below) drops, allowing the spring to push the piston. The high-pressure air then flows to the intermediate pressure chamber, re-increasing the pressure until it pushes the piston back into the valve seat. Piston-type regulators have a lot of their internal components exposed to the water and the outer elements, which makes them more prone to wear and tear.

In the Diaphragm-type first stages, the pressure drop in the intermediate pressure chamber when the diver inhales pulls the diaphragm, lifting the valve poppet from the valve seat. This allows the high-pressure gas to flow into the intermediate pressure chamber, re-increasing the pressure until the valve poppet gets back into its original position, acting as a seal. A diaphragm-type first stage is sealed off from the outer environment, making it more resistant to wear than a piston-type first stage.

Upstream vs Downstream

A second stage can either operate using an upstream or downstream valve. The key difference between the two types is the movement of the valve:

- In an upstream valve, the demand valve opens against the flow of the gas.

- In a downstream valve, the demand valve opens following the direction of the flow of gas, and is kept sealed using a spring. Most regulators today use a downstream valve.

Unbalanced vs Balanced

When a stage has an inflow of air that varies in pressure, the outflow can also vary. To give an example, when the pressure of the tank varies (drops) as the diver uses air throughout the dive, the interstage pressure may drop as well. If it does vary, the stage is called unbalanced. If the stage is engineered in such a way that it compensates for the variation in supply pressure to maintain a constant output pressure, the stage is called balanced.

Any type of stage can be balanced or unbalanced (a diaphragm or piston first stage, an upstream or downstream second stage can both be balanced or unbalanced). There may also be a combination of a balanced/unbalanced first/second stage in a regulator unit.

Cold-Water Regulators

Cold water poses a risk of a regulator freeze (which can happen in both the first and the second stage). When going through the stages of the regulator, the high-pressure air, which expands as it gets reduced to a lower pressure, cools down significantly; if the regulator is being used in cold water, the risk of stage freezing is larger: more specifically, the risk of a second stage freeze exists with in water with a temperature of 10°C (50°F) or less, and the risk of a first stage freeze exists in water with a temperature of 4.4°C (39.9°F) or less.

A regulator freeze can either happen when the internal moisture condensates and then freezes the internal parts, or when the water in direct contact with the first stage freezes.

Some regulators have unsuitable designs for cold-water diving (for example second stages where the exhale of the diver, which is humid, is in contact with the cold parts of the mechanism), and regulators that are suitable for cold water are specifically marked (usually on the first and second stage directly), or are described as such in their user manual.

Long-hose variant

On a normal regulator set, there are two second stages (a primary one and a secondary one, which we also call the octopus). While the octopus is usually longer than the primary second stage, there is a variant of this setup (called long hose), where there is one of the second stages that has a significantly longer hose (up to 2m long). In this setup, the diver uses the longer hose as their primary hose: the hose starts from behind the right shoulder, loops around their waist, goes back up to loop around their head from their right shoulder, and sits in front of the mouth of the diver. The shorter hose is used as a backup hose and is tied with a bungee around the neck of the diver, easy to access if needed.

This setup is known as being safer, as in an out-of-air situation, the diver will give their buddy their primary, long hose and quickly switch to their alternate, shorter hose; the long hose allows more movement between both divers. In a twinset configuration, a long hose setup is standard. Some agencies (such as RAID) start teaching from the open-water level with the long hose.

How to use a scuba diving regulator

Attaching the regulator to the tank

The first stage should be protected, as, although sturdy, it remains a weak point in the regulator as a whole and is susceptible to damage upon impact. If you are using a Yoke regulator, you should avoid screwing it too tightly or too loosely, but if you are using a DIN regulator, you should screw it into the valve as far in as you can. The screwing on process should be easy, and if there is some kind of resistance, you might have to angle the regulator better towards the valve of the tank: keep it as level as you can.

Once the first stage is properly screwed in/on the tank valve, make sure that the hoses aren't tangled and are positioned correctly. Tuck the alternate second stage (also called Octopus) in a pocket or a holder; attach the inflator hoses to your BCD; make sure that the pressure gauge (or manometer) is attached or tucked away so it doesn't get in the way.

Second Stages

The second stage(s) are the part of the regulator the diver is going to breathe directly from; as a user, there are three important parts on a second stage:

- The mouthpiece is the part that goes in the mouth and where the air flows out from. The diver should bite gently on the front of the mouthpiece while putting their lips as far back as they can. It isn't necessary to bite very hard; otherwise, the mouthpiece will simply get damaged. A damaged mouthpiece can simply be exchanged for a new one.

- The purge button is a button that can be found on the back of the second stage. Pressing this button manually opens a valve inside the second stage and allows air to flow through its casing. It is used in case water (or liquid in general) gets into the second stage, as pressing it clears it out. The purge button can also be used to force the regulator to free-flow, which can be useful in certain cases, such as inflating DSMBs.

- On some regulators, you'll be able to find an adjusting knob, which is used to adjust the cracking pressure (it works by screwing/unscrewing a spring, which varies the energy required to pull the demand valve). Adjusting this increases or decreases the required effort to breathe, which also increases/decreases the airflow from the second stage.

When breathing through the second stage, you should have slow, deep, and relaxed breathing. Breathing erratically or having too fast/shallow breaths will create a "dead air space" in the mouthpiece, preventing fresh, new air from being properly inhaled and keeping the CO2-rich air in your mouth and lungs. A stable and relaxed breathing pattern also allows for greater control of your buoyancy

Inflator hoses

Inflator hoses are low-pressure hoses that can be connected to specific ports found on BCDs, drysuits, and more. They allow the diver to inflate an air pocket/bladder using the gas from the tank. It is common for some divers to use a different, smaller pony bottle to inflate their drysuit. The standard for inflator hoses is to have a "quick disconnect fitting" system, where the metal tip has to be pulled back before pushing it on the inflator port, where it will click into place. Those types of fittings shouldn't be screwed/unscrewed, as it might open the system and cause it toleak. To disconnect the inflator hose from the port, the hose should be pushed in, before pulling back the tip, the hose will then easily disconnect.

SPG/Manometer

The SPG (or Submersible Pressure Gauge), also called a Manometer, allows the diver to monitor the pressure of their tank. To be able to do that, it needs to he connected to one of the high-pressure ports on the first stage (the high-pressure ports are directly fed by the high-pressure gas from the tank before it gets reduced to the intermediate pressure). The high-pressure ports have different connection and hoses than low-pressure ones! The SPG should be checked often to monitor your pressure.

Common regulator mistakes

- The first mistake we observe divers make with regulators is having an improper breathing pattern. Breathing is a very important part of diving, and it will impact your stress levels, buoyancy, and more. A good breathing pattern is a slow, regular, and deep one. Having the mouthpiece sitting improperly in the mouth can also result in suboptimal comfort and breathing; ensure that you have the mouthpiece fully in your mouth while gently biting down on it.

- Another common mistake divers make is, when setting up their gear, not making sure that the regulator is streamlined and attached where it is supposed to be: having messy gear and ending up with tangled hoses is a sure way to increase stress levels right at the beginning of a dive. To prevent that, as soon as your scuba unit is rigged, have a look at all the hoses (primary and alternate second stage, inflator hose, SPG, etc...), and ensure that they are attached where they are meant to be attached and that they don't tangle anywhere.

- A mistake divers make with their second stage, especially when doing skills, is: when taking out the second stage from their mouth in the water, they will accidentally point their mouthpiece towards the surface, which creates a path for the air to escape and initiates a free-flow. To prevent that from happening, ensure that the mouthpiece is pointed downwards at all times.

- A mistake made by beginner divers is not coughing or spitting through the second stage: it is common for new divers to either take out the regulator from their mouth to spit/cough, or even try to get back to the surface to cough/spit before getting back down. The second stage is engineered to be as sturdy as possible, and is able to withstand a coughing diver; for this reason, if you feel the urge to cough or spit, do it through the second stage!

Maintenance and Care Tips

To give your regulator as much life as possible, you need to take good care of it (the same goes for your other pieces of equipment as well). Let's have a look at the proper way to wash and store your regulator.

Washing/Cleaning the regulator

You should wash the regulator after each use/dive. If the regulator (that was in contact with your saliva) isn't washed after use and is then left unattended, it can become moldy relatively quickly. On top of that, if you were diving in salt water, cleaning the regulator with fresh water prevents the formation of salt crystals.

To correctly wash your regulator, dip the second stages, SPG, inflator hoses, and hoses in freshwater, which can optionally have a little bit of disinfectant mixed into it (we especially recommend adding disinfectant to wash rental regulators, as different people might be sharing them). Make sure the water goes inside the mouthpieces and any cavity where dirt might build up. When washing the first stage, do not submerge it as it is important not to put water inside the connection that screws on the tank: if water gets inside, it risks getting pushed further in the regulator by the flowing air, and rusting the first and second stage from the inside over time. To wash the first stage, we recommend slowly pouring water over the outer part, while avoiding the part that connects to the tank (you can use your hands to gently pour water over it). After washing, leave it to dry in a dry place.

Storing the Regulator

The regulator should be stored in a cool and dry environment. When you are finished using your regulator and want to store it for a certain amount of time, ensure it dries properly after washing it (you can leave it outside its case to dry for a day). After making sure the regulator is dry, use the regulator bag to store it and leave that bag somewhere without too much humidity and temperature fluctuations. If you leave your regulator without using it for a while, and when you decide to start using it again, inspect it visually to ensure there is no mold growth around the mouthpiece.

Servicing the Regulator

Servicing a regulator means changing all the parts that get used over time (O-rings, washers, etc...) inside the first and the second stage. On top of changing those replaceable and old parts for new parts, servicing the regulator includes an ultrasonic washing of the metal parts and casing to remove dirt and debris buildup. Only a certified technician can service a regulator (the technician needs to be certified for the specific brand of regulator he/she is servicing).

Price Range

Regulators can be purchased by individual pieces or as an assembled kit, depending on your needs (some kits are rigged for single backmount, some are rigged for twinser, some for sidemount, etc...). Let's have a look at the price range of purchasing a pre-assembled unit and the price range for each separate part:

- Pre-assembled regulator: a ready-to-use regulator can vary greatly in price, as each of its parts can also vary in price. If you are looking for cheaper options, the cheapest regulator sets will cost you around 400€. A mid-range regulator set, with a correct price to quality ratio, will cost you between 600-700€. A high-end regulator will cost you upwards of 1000€. Specialized regulator sets (such as twinset or sidemount regulator) may even cost more than that!

- First stage: If you decide to purchase a first stage by itself, you are looking at a range of 200€ for the cheapest option and 400€ for the higher-end options. Some extremely high-end first stages can cost as much as 600€.

- Second stage: the price range for second stages is relatively similar, with the cheapest second stages at a price tag of around 150€, and the most expensive, high-quality second stages costing up to 400€.

- SPG: the SPG (or Manometer) by itself will cost between 50€ and 100€, depending on the brand. If you have a leak with your SPG and want to change it, it is entirely possible that the issue stems from a defective O-ring or swivel, which is cheaper to change than to replace the full SPG. If you want to open it, always ask a certified technician (if you are not certified yourself) to do it to avoid accidentally damaging it further.

- Hoses: A standard hose will cost you between 20€ and 30€. Some high-quality hoses can cost as much as 50€-100€.

FAQ

Q: Why does my regulator free-flow? Freeflowing is a failsafe mechanism ensuring that if the regulator fails, the diver is provided with an abundant flow of air. If your regulator freeflows, it is likely that you are putting it with the mouthpiece facing the surface, which creates a path for the air to freeflow. To prevent that, make sure to always put the mouthpiece facing down. If you find it to freeflow too easily, you can turn the adjusting knob down to decrease airflow.

Q: Is the sound my regulator makes normal? If you are breathing on the surface, and you hear your second stage sounding as if it were blowing a raspberry, it is probably only the membrane vibrating. If you are unsure or if it is making another sound (and as we cannot explain each and every case in this article), ask your local dive instructor or certified regulator technician.

Q: Why does my regulator become cold? When there is a reduction in pressure in a gas medium, the temperature drops as well. This is what happens when the regulator reduces the pressure of the gas to reduce it to a breathable pressure. This phenomenon is especially noticeable in the first stage when a second stage is free-flowing: For this reason, in cold water, specific regulators must be used to prevent freezing in case of a free-flow.

Q: Can I cough through my regulator? Yes, you can cough through the regulator. Second stages are very sturdy and can handle a simple cough. They are so sturdy that you could even throw up through them without ascending to the surface, and you would be fine.

Q: Can I spit through my regulator? Yes, you can spit through your regulator.